Failure Analysis Process Summary

Background History: Every failure analysis project starts with collecting background information. This is done by phone or onsite visit or online meeting. There would not be any charge for this step. Our Associates will be reviewed information including photographs, video, and drawings etc. of the subject and discuss the circumstances of the problem. We will also be discussed the scope of the project, the metallurgical analysis and its requirement, and possible expenses. For the scope, it’s critical to have complete agreement on the problem to solve.

Determination of Project Approach: In this stage, we use our experience, training, and knowledge to design the roadmap for moving forward. This includes metallurgical analysis of the subject. Identify the proper testing methods and analyze data and samples to find root cause of the subject and prevent the recurrence. Also, the approach might also include review of standards, supplier data sheet, quality control data and end user data.

Financial Matter: Detailed costing of the project includes the scope of the project, the list of work to be done, and the outcome. After issuing the purchasing order (P.O.) or approval, we start working and complete the timelines. We always respect the time sensitivity of the failure analysis.

Testing and Data Analysis: In this stage, the pre-selected metallurgical tests are performed and collect all data. The obtained data combined with the given background information is used to discover the metallurgical cause of the problem and potential root causes. In this stage, the customer’s input is crucial to find the root cause. The testing data will direct the conditions that cause the failure. This analysis will also reveal if there was anything metallurgically incompatibility with the metal. But detailed background information often helps to discover the root cause. The customer’s knowledge about the subject design, manufacturing, and use are important.

Report Writing and Customer Support: After identifying the root cause, a detailed technical report will be prepared and presented to the customer. Once the customer gets report, we work with them for helping to understand how the failure or problem occurred, its root cause, and how to prevent it from reoccurring. We continue to support the customer throughout the implementation of the recommended changes. One reason to choose “The metallurgy Master Mind” is because of our endless customer support.

Expert Witness Service

- Failure analysis of metals/metallurgical failure analysis

- Detecting defects or evidence of abuse

- Determining physical, mechanical or chemical properties of materials

- Assisting with subrogation claims

- Developing precision evidence analysis protocols

- Determining specification compliance

- Evaluating patent infringement

- Delivering detailed and convincing deposition and trial testimony

- Conducting joint plaintiff and defendant investigations

- Coordinating with other outside engineering experts, testing, and support firms

- Advanced instrumentation and qualified expertise

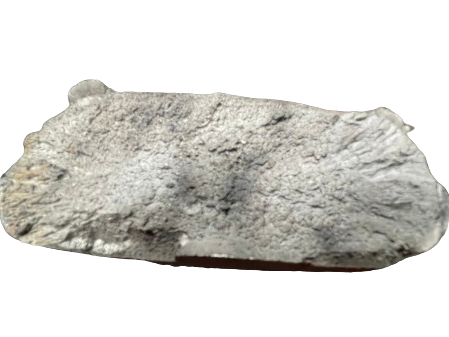

Visual Inspection (VT)

- Cracks

- Corrosion

- Surface flaws

- Banding

- Surface discontinuities

Please contact us for completed projects!

Our Past completed Projects

High cycle fatigue failure of fuel injector tip.

Hydrogen embrittlement of bolt-shank

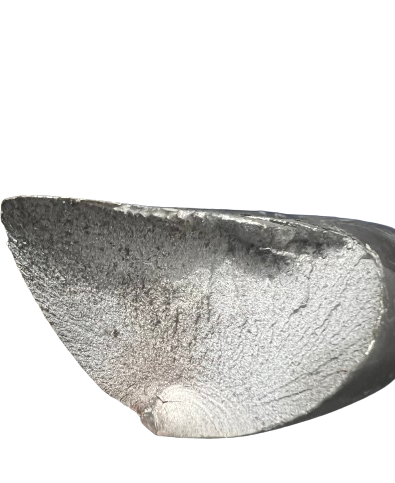

Brittle fracture due to use of inaccurate material

Low cycle fatigue failure due to over stressing

Brittle fracture of the leg due to casting defects

Our Current Projects

- Failure analysis of M10.8 hexa-bolt used for injector crab

- Failure analysis of inlet air tube used in blast furnace.

- Welding failure analysis of blower hub.

- Failure analysis of sedan car exhaust for expert witness.

Low cycle fatigue failure of helical spring

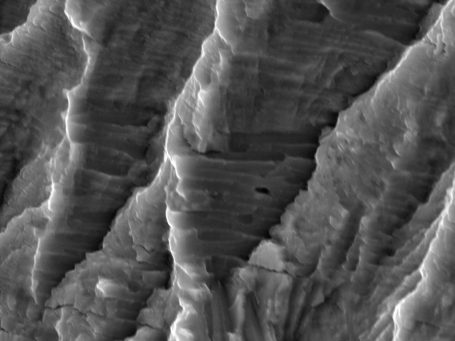

SEM image shows fatigue striation in A356 Aluminum alloy after 2M cycles.

Creep-fatigue failure of the high temperature helical spring of IN713

Low cycle fatigue failure due to use of inappropriate threading

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.